Product Description

Products

YOUR DESIGN WE HELP TO ACHIEVE, AS YOUR SINCERE PARTNER!

SINCERITY QUALITY COMPETENCE

General Products Application /Service Area:

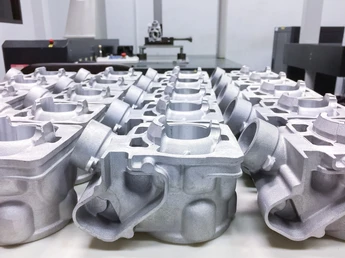

Metal parts for vehicle, agriculture machine, construction machine, transportation equipment, Valve and Pump system. E.g. Engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve, valve housing ,Fitting , flange, wheel, flywheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc.

| Application | |||||||||||||||||||||||||||||||

| • Agricultural equipment | • Armament | • Automobile industry | • Computing equipment | • Medical / dental instruments | • Measuring instruments | ||||||||||||||||||||||||||

| •Miscellaneous equipment | •Pharmaceutical industry | • Orthopedic implants | • Safety equipment | • Petrochemical industry | • Industrial valves | ||||||||||||||||||||||||||

| •Fixing and movable equipment | • Sanitary fittings | • General machinery | • Pumps and general connections | • Food and beverage processing | • Instrumentation equipment | ||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

Products shown here are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available within CHINAMFG group of companies.

Please send us your detailed drawing/ sample/requirements for us offering a reasonable quotation to you and we will trying our best to make the goods in good quality and delivery in time .

MATECH policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong.

Product Application

| Agricultural equipment | Armament | Automobile industry | Computing equipment |

| • Medical / dental instruments | • Measuring instruments | • Miscellaneous equipment | • Pharmaceutical industry |

| • Orthopedic implants | • Safety equipment | • Petrochemical industry | • Industrial valves |

| •Fixing and movable equipment | • Sanitary fittings | • General machinery | • Pumps and general connections |

Casting Equipment

Technical Support:

HangZhou Ketuohong Machinery Equipment., Ltd (KTH) is professional at independent development and design. Our engineers are skilled at AUTO CAD, PRO ENGINEER, UG, SOLID WORKS and other 2D & 3D softwares, and we have CHINAMFG mold flow software to simulate the casting process dueing tooling/die and p’re design. We are able to design, develop, produce and deliver your PO according to your drawings, samples or just an idea. Dural control of standard products and OEM products.

Quality Control:

1) Checking the raw material after they reach our factory——- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production—In process quality control(IPQC)

4) Checking the goods after they are finished—- Final quality control(FQC)

5) Checking the goods after they are finished—–Outgoing quality control(OQC)

Project Plan:

Our Factory

HangZhou Ketuohong Machinery Equipment., Ltd (KTH)

We specialize in Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system etc.

With keeping manufacturing process design, quality plHangZhou, key manufacturing processes and final quality control in house we are mastering key competence to supply quality mechanical parts and assembly to our customers for both Chinese and Export Market.

To satisfy different mechanical and functional requirements from our customers we are making a big range of metal products for our clients on base of different blanks solutions and technologies. These blanks solutions and technologies include processes of Iron Casting, Steel Casting, Stainless Steel Casting, Aluminum Casting and Forging.

During the early involvement of the customer’s design process we are giving professional input to our customers in terms of proces feasibility, cost reduction and function approach. You are welcome to contact us for technical enquiry and business cooperation.

How do We Work with Our Clients?

1. For a design expert or a big company with your own engineering team: we prefer to receive a fully RFQ pack from you including drawing, 3D model, quantity, pictures;

2. For a start-up company owner or green hand for engineering: just send an idea that you want to try, you don’t even need to know what casting is;

3. Our sales will reply you within 24 hours to confirm further details and give the estimated quote time;

4. Our engineering team will evaluate your inquiry and provide our offer within next 1~3 working days.;

5. We can arrange a technical communication meeting with you and our engineers together anytime if required.

Why choose us?

1. High skilled and well-trained working team under good management environment.

2. Quick response and support for any inquiries.

3. Over 10 years professional manufacture experience to ensure high quality of your products.

4. Large and strong production capacity to meet your demand.

5. High Quality standard and hygienic environment.

6. We have very strict quality control process:

In coming Quality control (IQC) – All incoming raw material are checked before used.

In process quality control (IPQC) – Perform inspections during the manufacturing process.

Final quality control (FQC) – All finished goods are inspected according to our quality standard for

each products.

Outgoing Quality Control (OQC) – Our QC team will 100% full inspection before it goes out for

shipment.

Proper Quarantine procedure – For those products got rejected to pass the quality control, they will

specially marked and dispose.

7. Good after sales services

8. Passed IATF16949:2016 and provide SGS/RoHS certification if needed.

Our Package

Inner Packing →Strong & waterproof plastic big is packed inside, to keep the product in safe condition.Or as customer requests.

Outer Packing →Multilayer wooden box with strong bandages, used for standard export package. Or customized as per customer’s requirements.

FAQ

1Q: Are you trading company or manufacturer?

A: We are a factory, so we can provide competitive price and fast delivery for you.

2Q: What kind of service can you provide?

A: Our company can provide custom casting, CNC machining and surface treatment according to customer’s requirements.

3Q: What’s kinds of information you need for a quote?

A: In order to quote for you earlier, please provide us the following information together with your inquiry.

1. Detailed drawings (STEP, CAD, CHINAMFG Works, PROE, DXF and PDF)

2. Material requirement (SUS, SPCC, SECC, SGCC, Copper, AL, ETC.)

3. Surface treatment (powder coating, sand blasting, planting, polishing, oxidization, brushing, etc.)

4. Quantity (per order/ per month/ annual)

5. Any special demands or requirements, such as packing, labels, delivery, etc.

4Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions (Thickness, Length, Height, Width), CAD or 3D file will be made for you if placed order.

5Q: What makes you different from others?

A: 1. Our Excellent Service

We will submit the quotation in 48 hours if getting detailed information during working days.

2. Our quick manufacturing time

For Normal orders, we will promise to produce within 3 to 4 weeks.

As a factory, we can ensure the delivery time according to the formal contract.

6Q: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with photos or videos which show the machining progress.

7Q: Can I have a trial order or samples only for several pieces?

A: As the product is customized and need to be produced, we will charge sample cost, but if the sample is not more expensive, we will refund the sample cost after you placed mass orders.

8Q: Why there is tooling cost?

A: It’s mold cost. Indispensable production process. Only need to pay for first order, and we will bear maintenance cost of mold damage.

9Q: What is your terms of payment?

A: Payment of sample order ≤ 1000USD, 100% T/T full payment.

Payment of tooling or batch order ≥ 5000USD, 70% T/T in advance, balance before shipment.

10Q: What’s your after-sale service?

A: If there is quality problem, please provide photos or test report, we will replace defective goods or return funds.

If you have any other questions please find us online, or send messages via email, WhatsApp for better communication!

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Auto Part, Machinery Accessories, Electronic Part |

|---|---|

| Machining: | CNC Machining/Lathing/Milling/Turning/Boring |

| Material: | Aluminum Alloy, ADC10, ADC12, A380, A356, Alsi10mn |

| Design: | 3D |

| Casting Tolerance: | CT5-7 for Aluminum Casting |

| Material Inspection Report: | Material Inspection Report |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | |

|---|

What design considerations are there when working with cast aluminium?

When working with cast aluminium, several design considerations should be taken into account to ensure successful and efficient manufacturing. Here’s a detailed explanation:

1. Wall Thickness: Maintaining uniform wall thickness is crucial in cast aluminium design. Thick sections can lead to slower solidification, increased porosity, and potential shrinkage defects. Conversely, excessively thin sections may result in poor mold filling and insufficient mechanical strength. Design guidelines should be followed to optimize wall thickness and ensure proper solidification during casting.

2. Corner Radii and Fillets: Incorporating generous corner radii and fillets in cast aluminium designs helps minimize stress concentration and prevent the formation of sharp edges. Smooth transitions between wall sections, ribs, and bosses improve the overall strength and integrity of the casting.

3. Draft Angles: Draft angles are necessary to facilitate the removal of the casting from the mold. Adequate draft angles allow for smooth ejection, reducing the risk of damage to the casting and ensuring consistent production. Typically, a minimum draft angle of 1-3 degrees per side is recommended for cast aluminium parts.

4. Rib Design: Ribs are often used to provide additional strength and rigidity to cast aluminium components. Designing ribs with proper thickness, height, and filleting helps prevent distortion and ensures effective heat dissipation during casting and subsequent use.

5. Undercuts and Core Pulls: Complex cast aluminium designs may require the use of cores or slides for creating undercuts or internal features. These features should be designed with care to allow for easy removal of the casting from the mold. Proper consideration of core placement, shape, and release mechanisms is essential to avoid casting defects and ensure smooth production.

6. Parting Line: The parting line is the interface where the two halves of the mold meet. It is important to carefully consider the location of the parting line to minimize the need for additional machining and to ensure good dimensional accuracy. The parting line should be strategically placed to avoid critical features and maintain the overall integrity of the casting.

7. Surface Finish and Texture: Cast aluminium parts often require specific surface finishes and textures for both functional and aesthetic purposes. Design considerations should be given to the desired surface finish, such as smoothness, textures, and the location of parting lines, to achieve the desired appearance and performance of the final product.

8. Material Selection: The selection of the appropriate aluminium alloy for the specific application is crucial. Different aluminium alloys have varying mechanical properties, corrosion resistance, and casting characteristics. Understanding the requirements of the part and selecting the suitable alloy will ensure optimal performance and cost-effectiveness.

9. Tolerances and Machining Allowances: Design tolerances and machining allowances should be carefully defined to accommodate the expected dimensional variations during casting and post-casting processes. It is essential to consider the shrinkage and distortion tendencies of cast aluminium and provide appropriate tolerances to achieve the desired fit and functionality of the final assembly.

10. Testing and Prototyping: Testing and prototyping are essential steps in the design process for cast aluminium parts. Physical prototypes and computer simulations can help identify potential issues, validate the design, and optimize the casting process before full-scale production. Performing thorough testing and evaluation ensures the final design meets the required performance and quality standards.

By considering these design considerations, engineers and designers can optimize the manufacturability, functionality, and performance of cast aluminium components. Collaboration between designers, casting experts, and manufacturers is often valuable to ensure the best outcomes in terms of cost, quality, and efficiency.

Are there any corrosion-resistant grades of cast aluminium?

Yes, there are corrosion-resistant grades of cast aluminium that are specifically formulated to have enhanced resistance against corrosion. Here’s a detailed explanation:

Cast aluminium alloys are typically composed of aluminium as the primary element and various alloying elements added to enhance specific properties. The choice of alloying elements and their composition can significantly influence the corrosion resistance of cast aluminium. Some commonly used corrosion-resistant grades of cast aluminium include:

- Aluminium-Silicon Alloys:

- Aluminium-Magnesium Alloys:

- Aluminium-Zinc Alloys:

- Aluminium-Copper Alloys:

Aluminium-silicon alloys, such as the popular A356 and A413 grades, are widely used in casting applications due to their excellent corrosion resistance. These alloys contain silicon as the primary alloying element, which forms a protective oxide layer on the surface of the aluminium, enhancing its resistance to corrosion caused by exposure to moisture, salts, and other corrosive elements.

Aluminium-magnesium alloys, such as the 5000 series (e.g., 5052 and 5083), are known for their good corrosion resistance. The addition of magnesium provides a self-healing property to the aluminium, as the magnesium reacts with oxygen to form a protective magnesium oxide layer. This oxide layer helps prevent further corrosion and degradation of the aluminium surface.

Aluminium-zinc alloys, such as the 7000 series (e.g., 7075), exhibit high strength and good corrosion resistance. The addition of zinc enhances the corrosion resistance by forming a protective zinc oxide layer on the surface of the aluminium. These alloys are commonly used in applications where both strength and corrosion resistance are critical, such as in aerospace and military industries.

Aluminium-copper alloys, such as the 2000 series (e.g., 2024), are known for their high strength and moderate corrosion resistance. The addition of copper improves the overall strength and mechanical properties of the aluminium, while also providing some degree of corrosion resistance. However, these alloys may require protective coatings or surface treatments for enhanced corrosion protection in more aggressive environments.

It’s important to note that while these corrosion-resistant grades of cast aluminium offer improved resistance to corrosion, they may still require proper maintenance and care to ensure their long-term performance. Factors such as exposure to harsh environments, temperature variations, and the presence of corrosive agents can still affect the corrosion resistance of cast aluminium, albeit to a lesser extent compared to non-resistant grades.

When selecting a specific grade of cast aluminium for a particular application, it is essential to consider the environmental conditions, intended use, and required level of corrosion resistance. Consulting with material suppliers or experts in the field can provide valuable guidance in choosing the most suitable corrosion-resistant grade of cast aluminium for a given application.

What are the common uses for cast aluminium products?

Cast aluminium products find numerous applications across various industries. Here’s a detailed explanation:

- Automotive Industry:

- Aerospace Industry:

- Building and Construction:

- Electrical Industry:

- Automotive Industry:

- Aerospace Industry:

- Building and Construction:

- Electrical Industry:

- Consumer Goods:

- Industrial Equipment:

Cast aluminium is widely used in the automotive industry for various components. Engine blocks, cylinder heads, transmission housings, intake manifolds, and wheel rims are some examples of cast aluminium products used in automobiles. The lightweight and corrosion-resistant nature of cast aluminium make it ideal for improving fuel efficiency and reducing overall vehicle weight.

The aerospace industry extensively utilizes cast aluminium products for aircraft components. Cast aluminium is used in the production of structural parts, engine components, brackets, and housings. Its combination of strength, light weight, and thermal conductivity makes it suitable for aerospace applications where weight reduction and high performance are critical.

In the building and construction sector, cast aluminium products are used for various purposes. These include window frames, door frames, decorative elements, railing systems, and structural components. Cast aluminium’s malleability, corrosion resistance, and ability to replicate intricate designs make it a popular choice for architectural applications.

Cast aluminium is utilized in the electrical industry

What are the common uses for cast aluminium products?

Cast aluminium products find numerous applications across various industries. Here’s a detailed explanation:

Cast aluminium is widely used in the automotive industry for various components. Engine blocks, cylinder heads, transmission housings, intake manifolds, and wheel rims are some examples of cast aluminium products used in automobiles. The lightweight and corrosion-resistant nature of cast aluminium make it ideal for improving fuel efficiency and reducing overall vehicle weight.

The aerospace industry extensively utilizes cast aluminium products for aircraft components. Cast aluminium is used in the production of structural parts, engine components, brackets, and housings. Its combination of strength, light weight, and thermal conductivity makes it suitable for aerospace applications where weight reduction and high performance are critical.

In the building and construction sector, cast aluminium products are used for various purposes. These include window frames, door frames, decorative elements, railing systems, and structural components. Cast aluminium’s malleability, corrosion resistance, and ability to replicate intricate designs make it a popular choice for architectural applications.

Cast aluminium is utilized in the electrical industry for products such as electrical enclosures, power transmission equipment, and heat sinks. The excellent thermal conductivity of aluminium helps dissipate heat generated by electrical components, ensuring optimal performance and preventing overheating.

Cast aluminium products are commonly found in various consumer goods. Cookware, including pots, pans, and baking trays, often utilizes cast aluminium due to its excellent heat distribution properties. Additionally, furniture, lighting fixtures, and decorative items may also incorporate cast aluminium for its aesthetic appeal and durability.

Cast aluminium is used in the manufacturing of industrial equipment and machinery. Pump housings, valves, gears, and various machine components can be made from cast aluminium. Its lightweight nature, corrosion resistance, and ability to withstand demanding environments make it suitable for industrial applications.

These are just a few examples of the many applications of cast aluminium products. The versatility, strength, and cost-effectiveness of cast aluminium make it a popular choice in industries where lightweight, durable, and corrosion-resistant materials are required.

editor by CX 2023-12-18